Fireproofing Inspector

Is inspection important in passive fire protection (PFP)

- Fireproofing and firestopping are highly technical, where control parameters of fire resistance/ PFP vary with various codes, type of protection material, test standards, designs, product data sheet, surface preparation, and installation.

- Some aspects of quality is not known to construction engineers and also not defined commonly.

- While inspections for fire certificate, the authority may require documents having data on material inspection, process quality control report and field quality report.

- Third party inspection under certified professional Inspector covers quality aspects of fire protection

Our Inspectors

- PFC has pool graduate engineers with 3-5 years of experience in to surface coating, firestopping and fire proofing,

- The experience includes in cellulose and hydrocarbon fire.

- The engineers are periodically trained and supervised by ICorr Qualified Inspector.

Areas of inspection

FIRE PROOFING

- Spray applied fire resistive material- SFRM ( Vermiculite or perlite of Gypsum or cementitious base)

- Intumescent fire resistive material – IFRM ( Solvent and water born coating)

- Epoxy PFP

FIRE STOPPING

- Firestop designs with Firestop mortar, composite sheet, sealant, putty, expanding foam.

- Curtain wall and expansion joint sealing.

- Cable fire proofing & partition wall

Inspection of fireproofing :vermiculite/ Perlite spray/ Intumescent spray

Material quality

- Fireproofing Material Certification mark, Self life, Condition of receipt, QA certificate,

- Lath quality, Storage condition

Preparatory

- Substrate condition, climatic condition, mock up, Surface preparation , Pinning and reinforcement process,

- Material preparation , Spray equipment,

Spray Process

- Spray and inter-coats process, curing process.

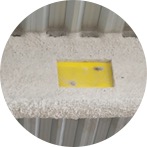

- Thickness control and compliance, Compliance to normative requirement ( Coat back, Flute gaps)

- Remedial and repair, Aesthetics . Over quote (Top coat , sealer coat etc)

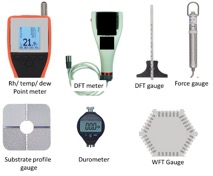

Field Quality (Sampling as per technical Manual 12 A & B)

- Thickness test ASTM E 706

- Density test ASTM E 706

- Bond test. ASTM E 736

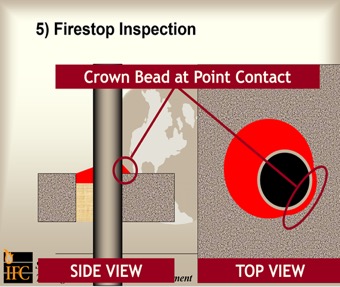

Inspection of firestopping

NBC Guideline: Through penetration firestop

Part 4 , section2.28/ 2.32, fire resistance rating for the firestop systems are established by using the test procedure by approved and accepted method. IS 12458 provides tests for firestop which covers, no flame pass, limited conduction temperature pass and withstanding of hose stream. ASTM E 814/ UL1479 is very elaborative and have widest acceptability.

NBC Guideline: Curtain wall Joint and Expansion Joint :

Joint seals are covered in Section 2.32 and Curtain wall seals are covered in 3.4.10.2 which directs for sealing the gaps with a accepted systems with a fire rating not less than the barrier. This sealing also work as smoke seal. Hence standard ASTM E 2307 and UL 2047 are to be used for meeting the purpose in accepted manner.

Firestop Installations:

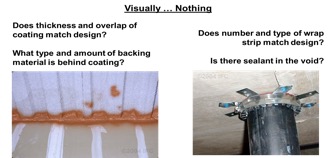

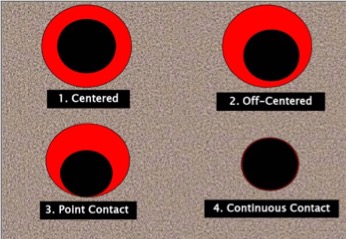

- Firestops for a opening/ gaps shall comply to a tested design , where Maximum size, Maximum Dimension, type and size of penetration, annular space, number of penetrations at the situation shall be within the limit provided in the design.

- The firestop installed shall be of same material, same thickness of application and assembled in same way as in design.

- In case of deviations, the installation shall comply engineering Judgement issued by the OEM or expert.

Inspection guideline

International Firestop Council (IFC ) provides guidelines for inspections, through tutorials on application method and measurement method. Inspections are carried as per ASTM E 2174 and 2393