The pre-construction phase is central to the success of the entire project. Yes, the entire project’s success is built upon the understanding of the this design stage and align the project accordingly. An outlook is given for carrying out risk assessment on “Passive fire protection” measures at this stage to :

- Minimise the installation period

- Minimise cost over run

- Minimise situational deviations from certified designs

- Minimise code compliance citations

FIREPROOFING

- Selection of Steel members

Fire proofing is one of major cost in steel structure building. The quantity of fireproofing material involved is based on section factors of load supporting steel members like Columns, Primary beams and secondary beams. A careful selection of structural design involving lower Hp/ A or higher W/ D shall reduce total cost of fireproofing material and application.

- Substrate Preparation

Many fireproofing material require specific profile and protection of substrate like abrasive blasting, and priming with compatible primer. A decision before may avoid rework before fire proofing.

- Selection of Fireproofing Material

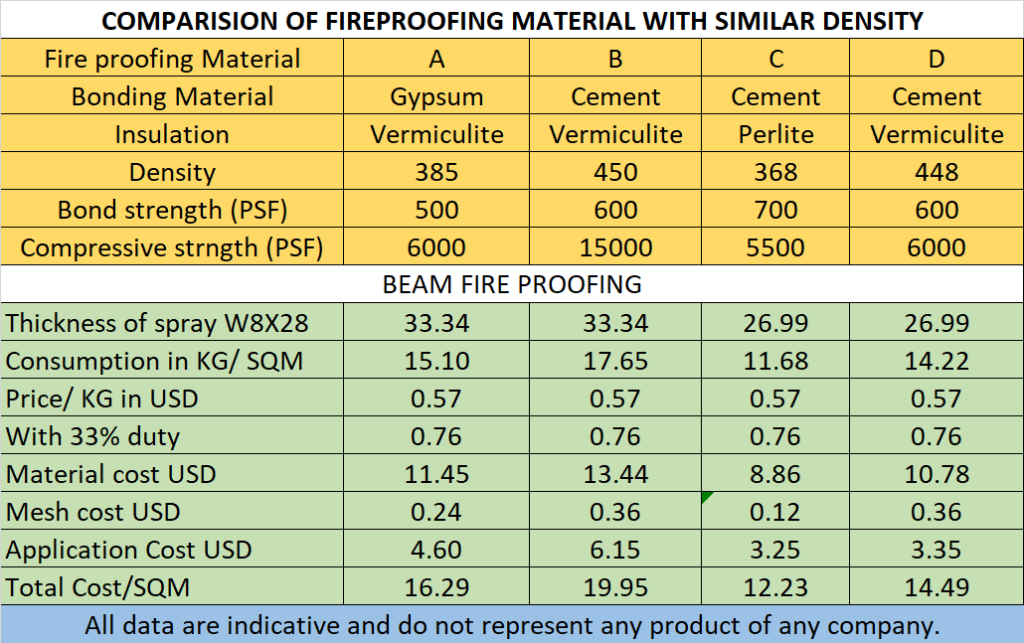

Fireproofing material have different density, hardness, bonding strength, but for code compliance and aesthetics, one may not make specification of best combinations. Even if two material are comparable in these parameters, a material may require higher thickness of spray compare to another. Some time a material can be applied in one coat, where the other one may require two coats. Many material require reinforcement when the thickness of spray is more.

- Selection of Fireproofing Design

UL 263 has listed many designs for same material and similar floor assembly. A careful design selection can reduce spray time, quantity and cost. Some designs require application of expanded metal lath, which is expensive installation.

FIRESTOPPING

- Designing Standard opening for MEP Services :

All opening for MEP shall be of few standard size and passing close to barrier edges . May be few UL designs shall be suggested before to be followed for opening creation and passing services accordingly. This shall greatly reduce, firestopping areas, situational deviations, requirement of EJ etc.

- Selection of few designs based on one or two type of firestop material:

Standardisation provides quicker installation and common material to work. Quick inspection and compliance citations.

CURTAIN WALL JOINT SEAL

- Assembly of curtain wall design and gap:

If a curtain wall assembly is complying a standard design of Joint sealing under ASTM E 2307, the sealing is less expensive quick. If it varies in all levels of building, compliance with a standard design become highly difficult and shall require more material and work content.

SUMMERY

Normal procedure for fire planning PFP is after design activity is complete. However, if a assessment for PFP is carried in designing stage, the cost of PFP work can be optimised , completed without time over run with less compliance citation. A consultant or third party expert may be consulted during the stage for accomplishing the benefit.